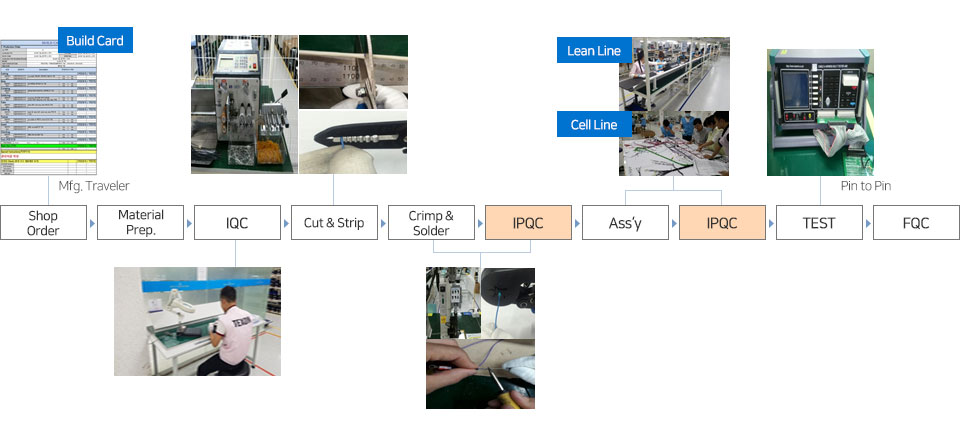

Manufacturing Process

Manufacturing Process

텍슨Texon develops, manufactures and supplies the products demanded by customers based on our technology in the field of communication and semiconductor businesses.

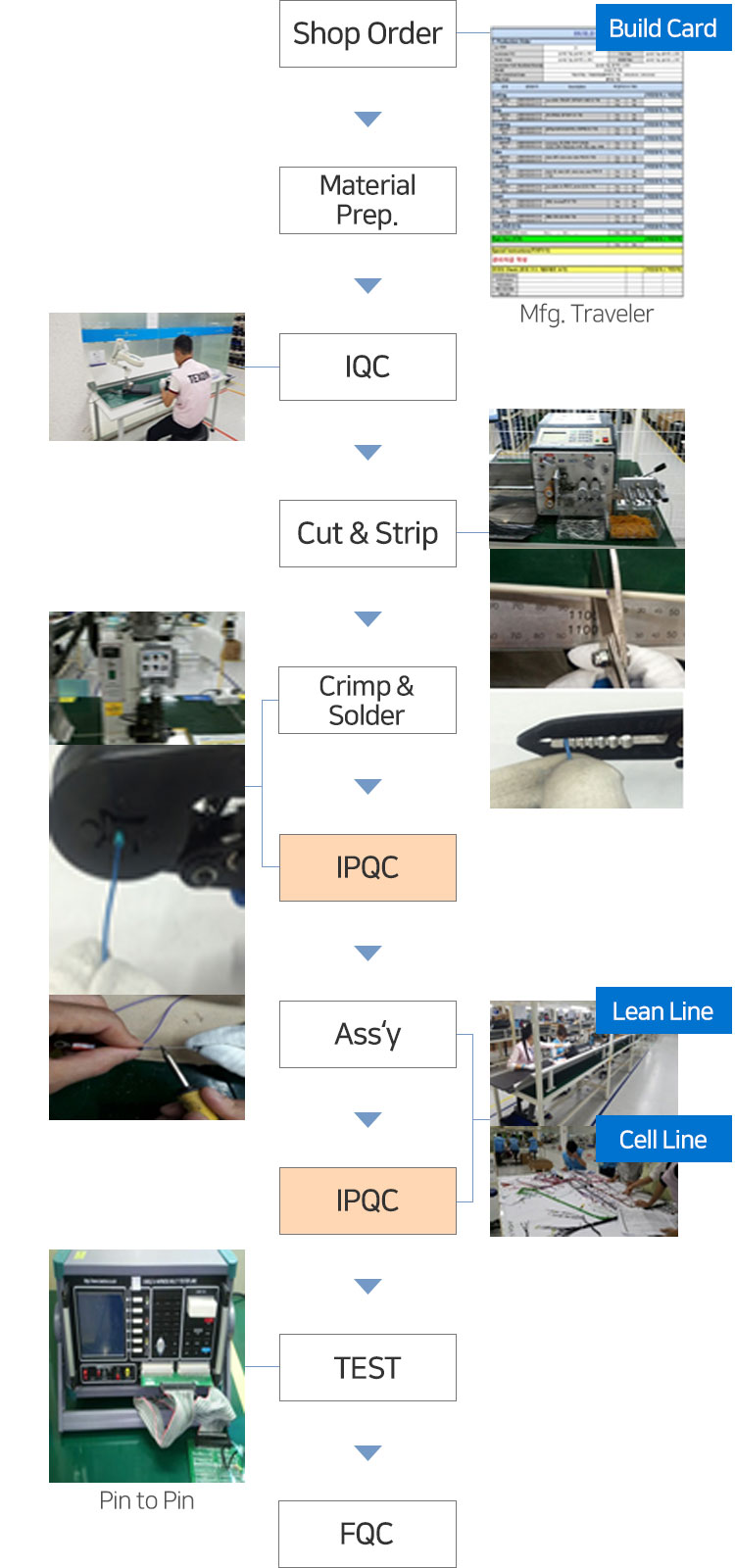

Sheet Metal

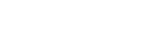

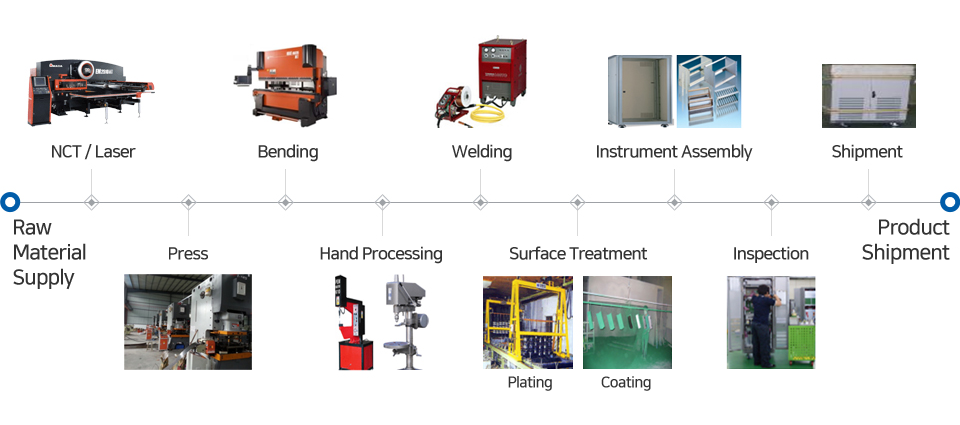

It is a manufacturing facility that can produce cabinets or enclosures through press, laser, NCT, bending and welding with the manufacturing method using sheet materials. With the latest equipment, it is possible to produce the product that meets customer’s specifications with precision after processing. We mainly produce cabinets up to 2.5m high, which are used for communication base stations, ESS, emergency power supply, and data center.

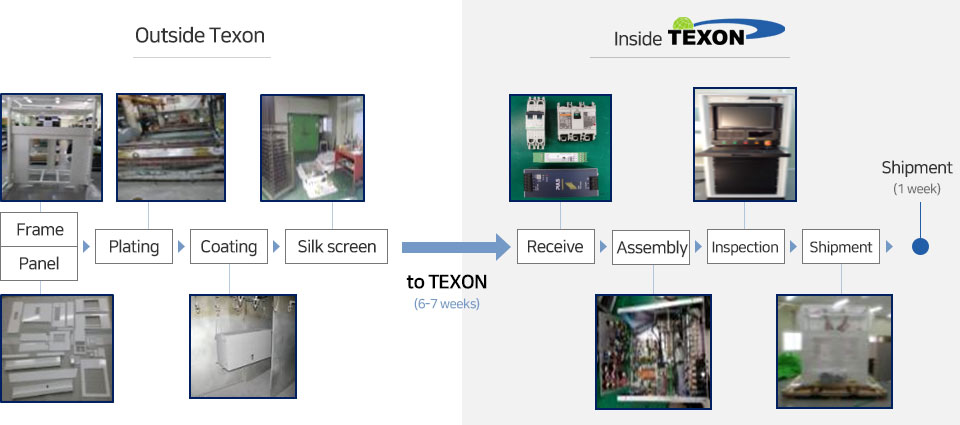

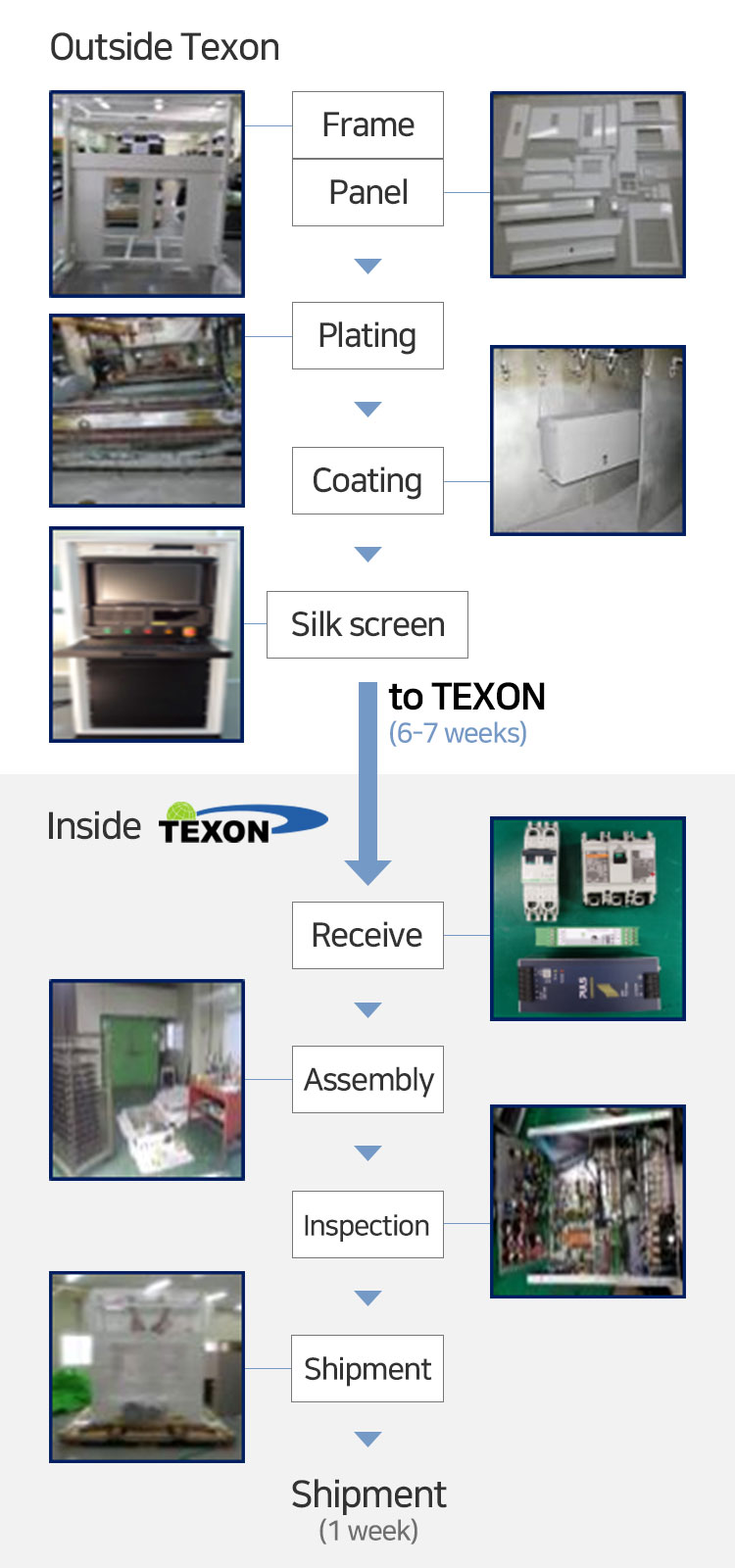

Manufacturing Flow Chart

LASER

| Equipment Name | Model | Manu-facturer | Quantity | Location |

| LASER | LCG-3015 | AMADA | 1 | Korea |

| FO-3015 | AMADA | 1 | Vietnam |

NCT

| Equipment Name | Model | Manu-facturer | Quantity | Location |

| NCT | EMZ-3510 | AMADA | 1 | Korea |

| PAGA-357 | AMADA | 1 | Korea | |

| PAGA-357 | AMADA | 2 | Vietnam | |

| EM-2510 | AMADA | 2 | Vietnam | |

| AC-2510 | AMADA | 1 | Vietnam | |

| VIPROS 2510 | AMADA | 1 | Vietnam |

BENDING

| Equipment Name | Model | Manu-facturer | Quantity | Location |

| BENDING | HDS-1303 | AMADA | 1 | Korea |

| HDS-1303 | AMADA | 1 | Vietnam | |

| HDS-8025 | AMADA | 1 | Vietnam | |

| RG-200 | AMADA | 1 | Korea | |

| RG-100 | AMADA | 1 | Korea | |

| RG-80 | AMADA | 1 | Vietnam | |

| RG-35 | AMADA | 1 | Korea | |

| RG-35 | AMADA | 2 | Vietnam | |

| FBD-8025 | AMADA | 1 | Vietnam |

WELDING M/C

| Equipment Name | Model | Quantity | Location |

| SPOT WELDING M/C | 350A | 1 | Korea |

| 350A | 2 | Vietnam | |

| WELDING M/C | 350A | 3 | Korea |

| 500A | 2 | Vietnam | |

| 350A | 25 | Vietnam | |

| 500A | 5 | Vietnam |

Press

| Equipment Name | Classification | Manu-facturer | Vietnam |

| Press | 20T | Kumsung Heavy Industries, SSangyong Precision | 16 |

| 80T | |||

| 110T | |||

| 160T | |||

| 200T | |||

| 250T |

Injection

| Equipment Name | Classification | Quantity | |

| Vietnam | Korea | ||

| BONA | 178t | 5 | – |

| Woojin | 55t | 1 | – |

| 85t | 1 | – | |

| 130t | 1 | – | |

| 150t | 1 | – | |

| Hyundai | 150톤 | 1 | – |

| 350t | 1 | – | |

| 450t | 1 | – | |

| Jinhwa | 650t | 1 | – |

| Total | 13 | – | |

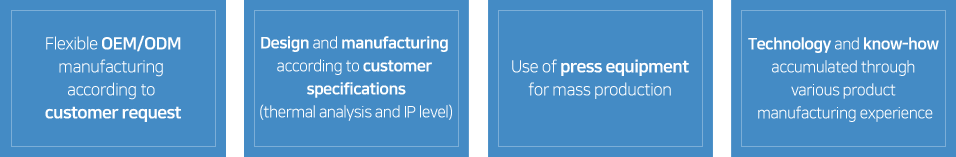

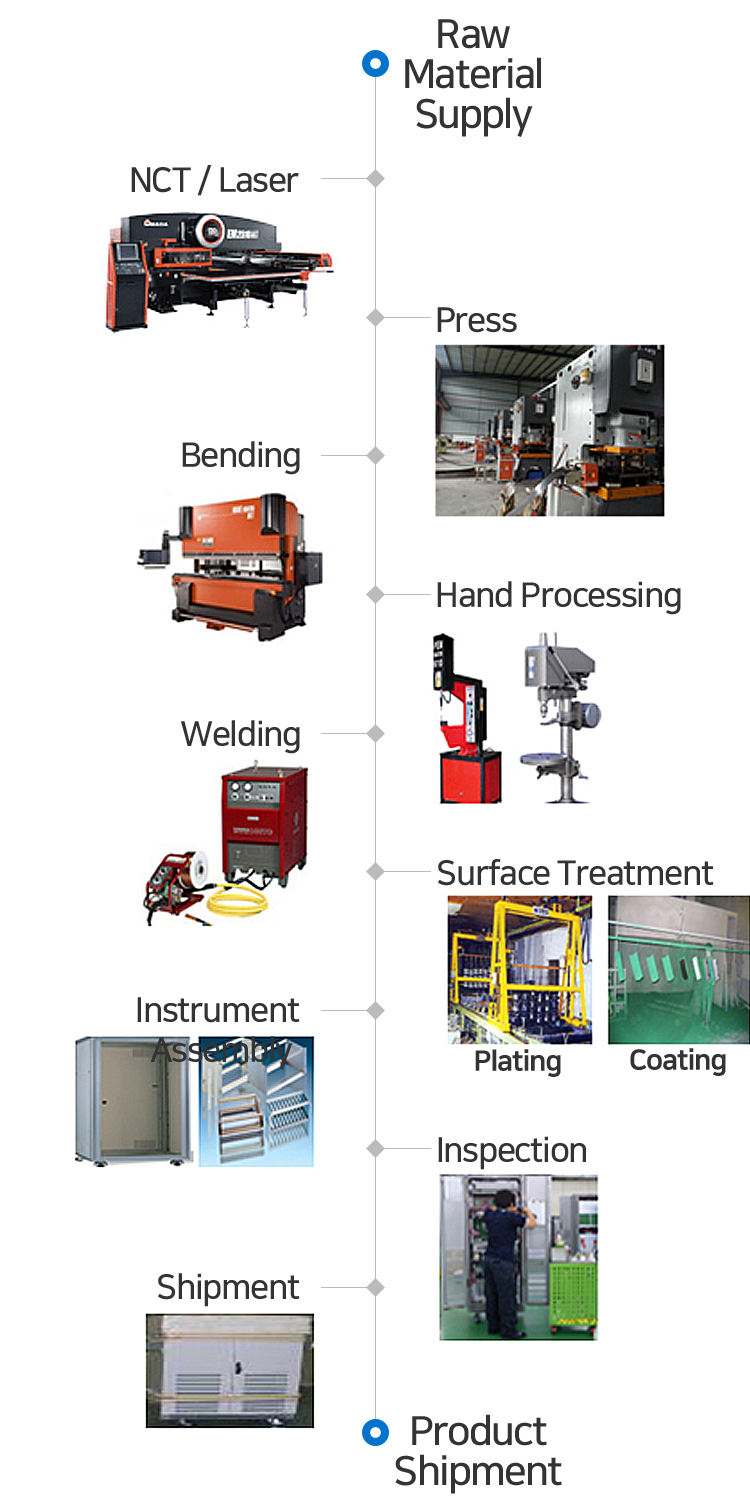

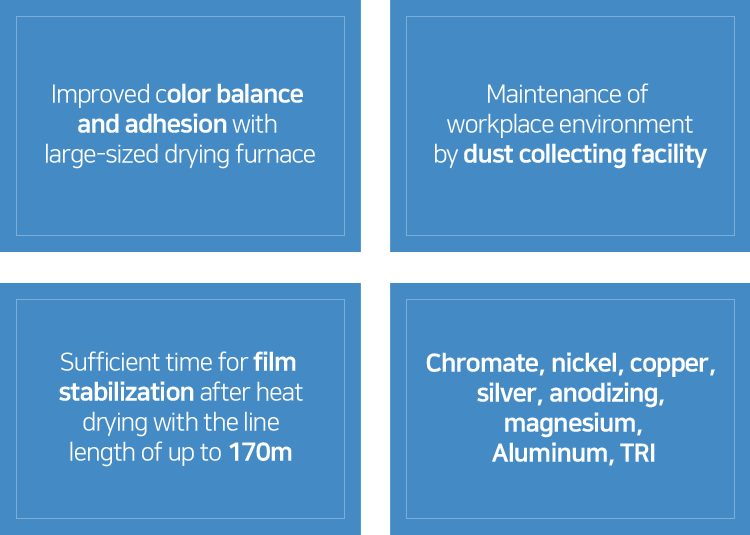

Plating & Coating

The durability of the products are improved by applying the type, thickness and color of the coating according to the customer’s specification with professional workforce and the latest equipment. With the experience of producing various industrial products, we can produce products in any specifications and also mass-produce large-scaled heavy goods utilizing work environment, equipment and technical manpower.

Post-processing

| Division | Category | Manufacturing Line |

| Plating | CHROMATE | 1 |

| Ni(Nickel) | 1 | |

| Cr(Chrome) | 1 | |

| ANO-DIZING | 1 | |

| Cu(Copper) | 5 | |

| Ag(Silver) | 1 | |

| Mg(Magnesium) | 1 | |

| Al(Aluminum) | 1 | |

| Coating | Liquid | 4 |

| Powder | 10 | |

| XY Line | 1 | |

| Spindle Line | 1 |

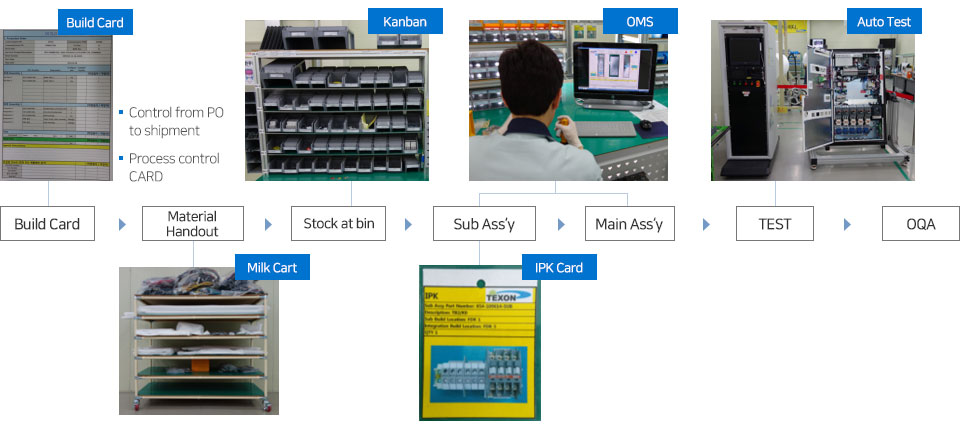

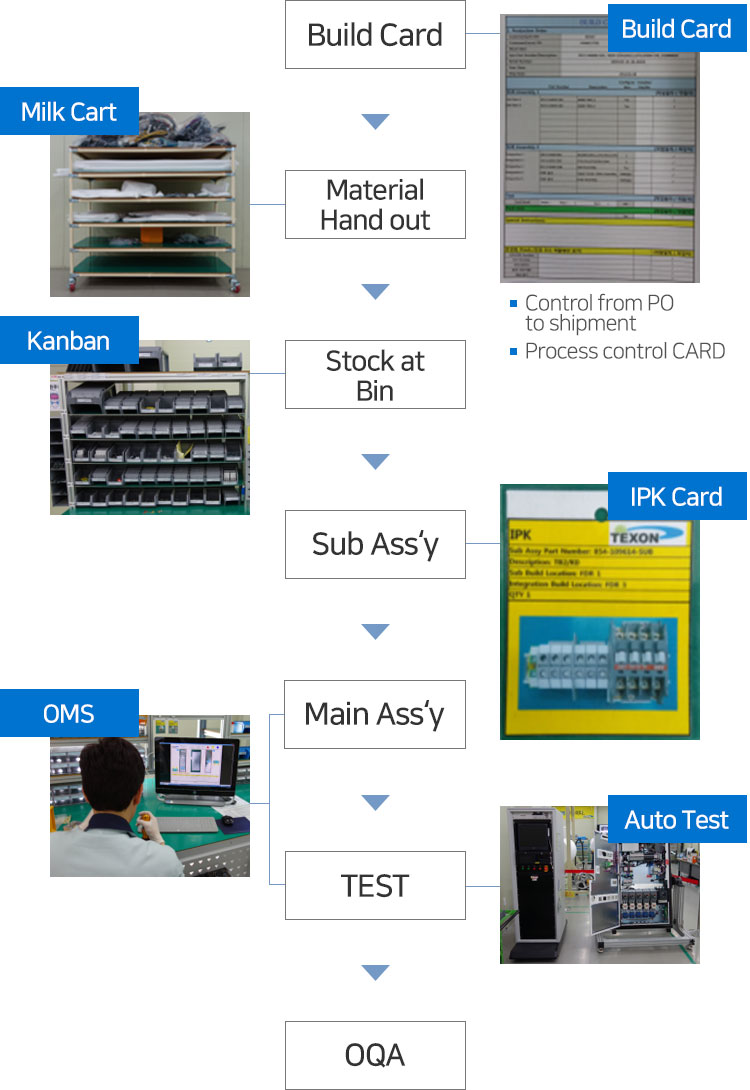

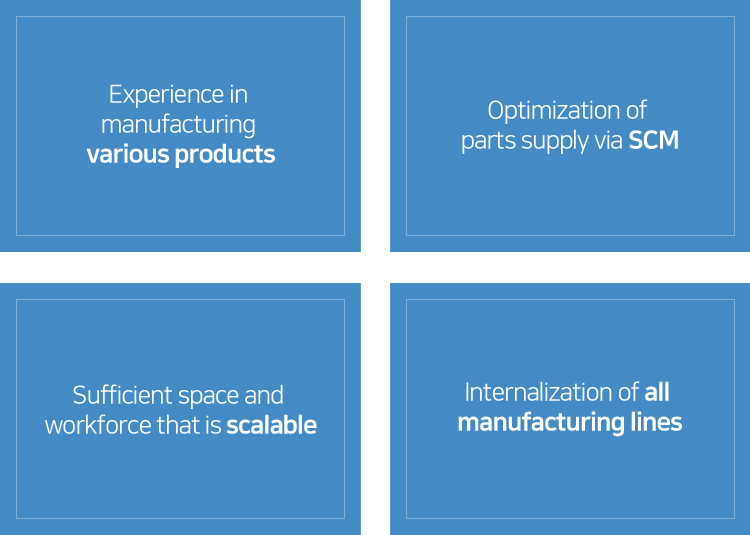

Assembly

The manufacturing line from raw material procurement to assembly and shipment is configured according to customer request based on the SCM with the production of the final EMS (Electronic Manufacturing Service). Both of the lean line and cell line can be configured, as well as the assembly of small to large-sized equipment depending on product and assembly method. We can directly control manufacturing and produce with all proprietary processes from A to Z using the production lines all internalized in Vietnam factory.

| Division | Korea | Vietnam (Communication) |

| Work Place | 3900 m2 | 6600 m2 |

| (1200 m2) | (2000 m2) | |

| Work Bench | 10ea/ | 10ea/ |

| 18 lines | 30 lines | |

| Capacity | 500 unit/ | 3000 unit/ |

| 1 day | 1 day |